Plastic Injection Moulding Services.

✔ UK Injection Moulding

✔ Short Lead Times

✔ Variety of Materials Available

✔ Skilled Staff Enforced Quality Control

UK Injection Moulding Specialists

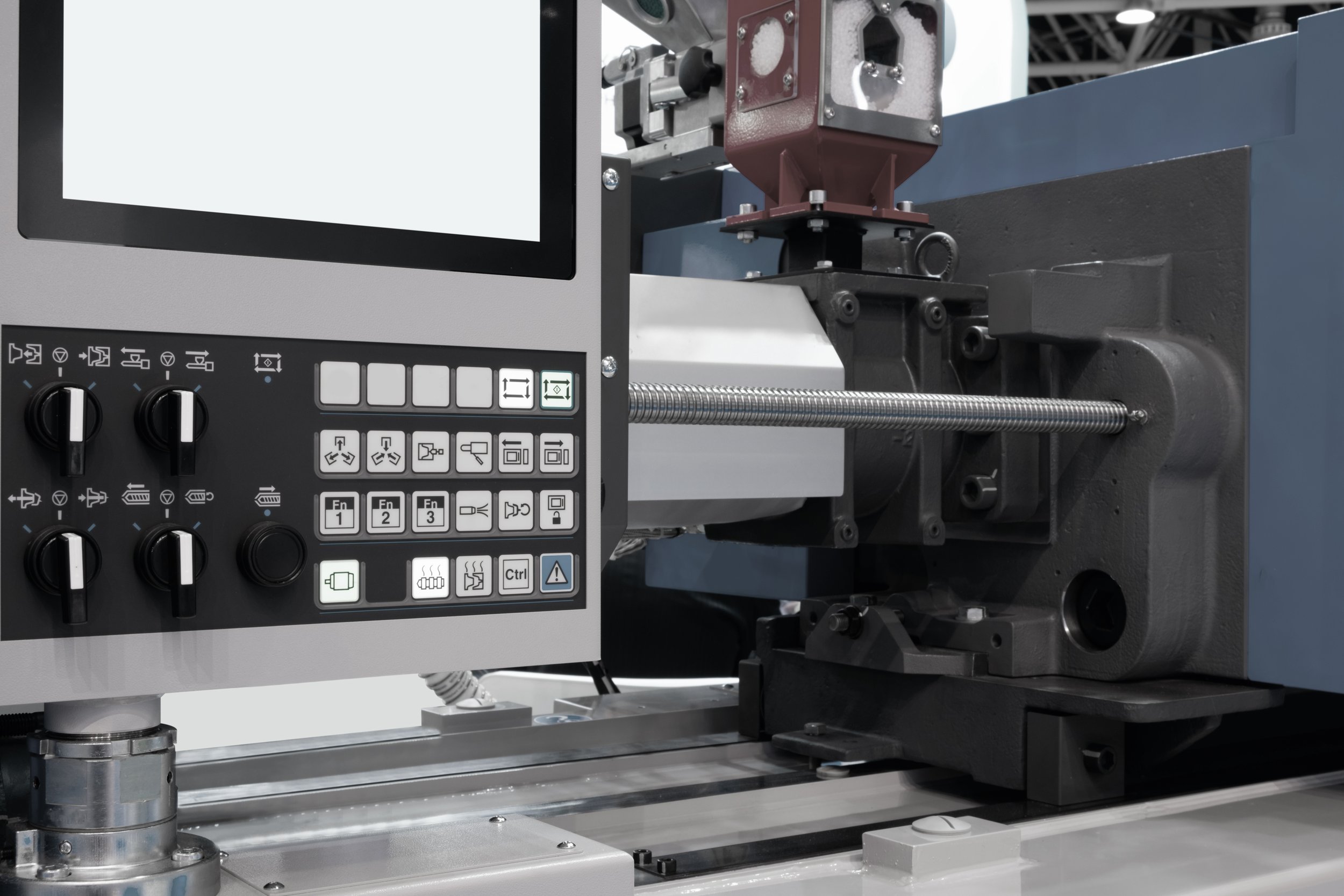

We have decades of experience manufacturing custom plastic injection moulded parts for clients to exact specifications. Operating from our factory in Sunbury-on-Thames, west London, utilising our state-of-the-art Hiatian moulding machines controlled by our skilled moulding technicians, we can rapidly and reliably deliver high quality mouldings to customers.

Commission A Mould

If you’re considering mass production of a plastic part, injection moulding may well be the ideal manufacturing process.

Before a single injection moulded part can be produced however, the mould itself - a precision engineered tool, designed to produce hundreds of thousands of moulded parts - must itself be built.

If you don’t have a mould, we can assist. Read more about our mould tooling services here.

Transfer A Mould

If you have a mould and need a reliable London based manufacturer with strict quality control to safely store moulds and efficiently manufacture your items as required, we can assist.

Transfer your mould to us and our team of machine setters will test and closely monitor its performance from initial trials right through to production, making necessary adjustments to ensure that it runs at optimum efficiency, with correct temperatures, speeds and pressures maintained over the production cycle.

Short Lead Times

S.B. Weston has numerous clients for whom it has produced injection moulded parts consistently for decades. You can rely on us to manufacture and deliver quality mouldings to a deadline and without delay thanks to our selection of available injection moulding machines which gives us plenty of production flexibility even at peak times.

Diverse Variety Of Materials Available

We can offer a diverse range of materials for manufacture including Polypropylene, Polyethylene, ABS and Acetal. Our machines allow tolerances to be set and will report an error if parameters are broken. Should a substandard moulding get through these mechanical tolerance checks it will be detected by manual quality control checks and visual monitoring by our machine operators. Our operators receive full training with regards to the unique quality control criteria of your mouldings.

Our setters and operators have many years of experience and a firm understanding of the precision controls used to maintain the sensitive injection moulding process. This enables us to deliver optimum quality mouldings across your entire production run as standard.

Free Consultation

We offer a free, no obligation, project consultation where we can discuss your exact requirements and advise how to best proceed. Just drop us an email and we can arrange an online video call or If you’re in the west London area then why not pop in, we’re always happy to meet face-to-face at our factory in Sunbury-on-Thames.

Hit that contact us button! We’d love to help make your project a British manufacturing success!

What Happens During the Injection Moulding Process?

Injection Moulding is a manufacturing process in which molten plastic is injected into a mould cavity, where it cools and hardens to the shape of the mould. This process is highly efficient for mass production of identical parts with tight tolerances.

Key Steps in the Injection Moulding Process.

1. Clamping

The process begins with the clamping of the mould. The mould is typically made of two halves: the cavity and the core. These halves are held together by the clamping unit on the injection moulding machine, ensuring they stay securely closed during the injection process.

2. Injection

Plastic pellets are fed into the injection moulding machine via a hopper. These pellets are then heated to a molten state and injected into the mould cavity through a nozzle and runner system. The injection speed and pressure are carefully controlled to ensure the material fills the entire mould cavity.

3. Cooling

Once the molten plastic fills the mould, it begins to cool and solidify. Cooling channels within the mold help to speed up this process by circulating cold water, around the mould. Proper cooling is essential to maintain the integrity and dimensional accuracy of the part.

4. Ejection

After the part has cooled sufficiently, the mould opens, and an ejection system pushes the part out of the mould. Ejector pins or plates are commonly used to release the part without damaging it.

5. Finishing

The final step involves any necessary post-processing, such as trimming excess material (flash), painting, printing on or assembling multiple components. Some parts may require additional quality checks to ensure they meet specifications.

Advantages of Injection Moulding as a Manufacturing Process.

1. High Efficiency: Once the initial setup is complete, the production process is extremely fast, making it ideal for high-volume manufacturing.

2. Precision and Consistency: Injection Moulding produces parts with high precision and repeatability, ensuring consistent quality across large production runs.

3. Material Versatility: A wide range of thermoplastic and thermosetting polymers can be used, allowing for diverse applications.

4. Complex Geometries: Intricate designs and complex shapes can be easily produced with the right mould design.

Applications of Injection Moulding.

Injection Moulding is used across various industries, including:

- Automotive: Manufacturing components like dashboards, bumpers, and interior panels.

- Consumer Goods: Producing items such as containers, toys, and electronic housings.

- Medical: Creating medical devices, syringes, and surgical instruments.

- Packaging: Making caps, closures, and packaging containers.

Is Injection Moulding right for your project?

At S.B. Weston our experienced team of plastic moulding designers and engineers can help you understand the key steps and advantages of the injection moulding process and how to utilise it to help you achieve a successful manufacturing project. If a different manufacturing process is more suited to your product then we can advise as to how you might proceed and quite possibly recommend a supplier.