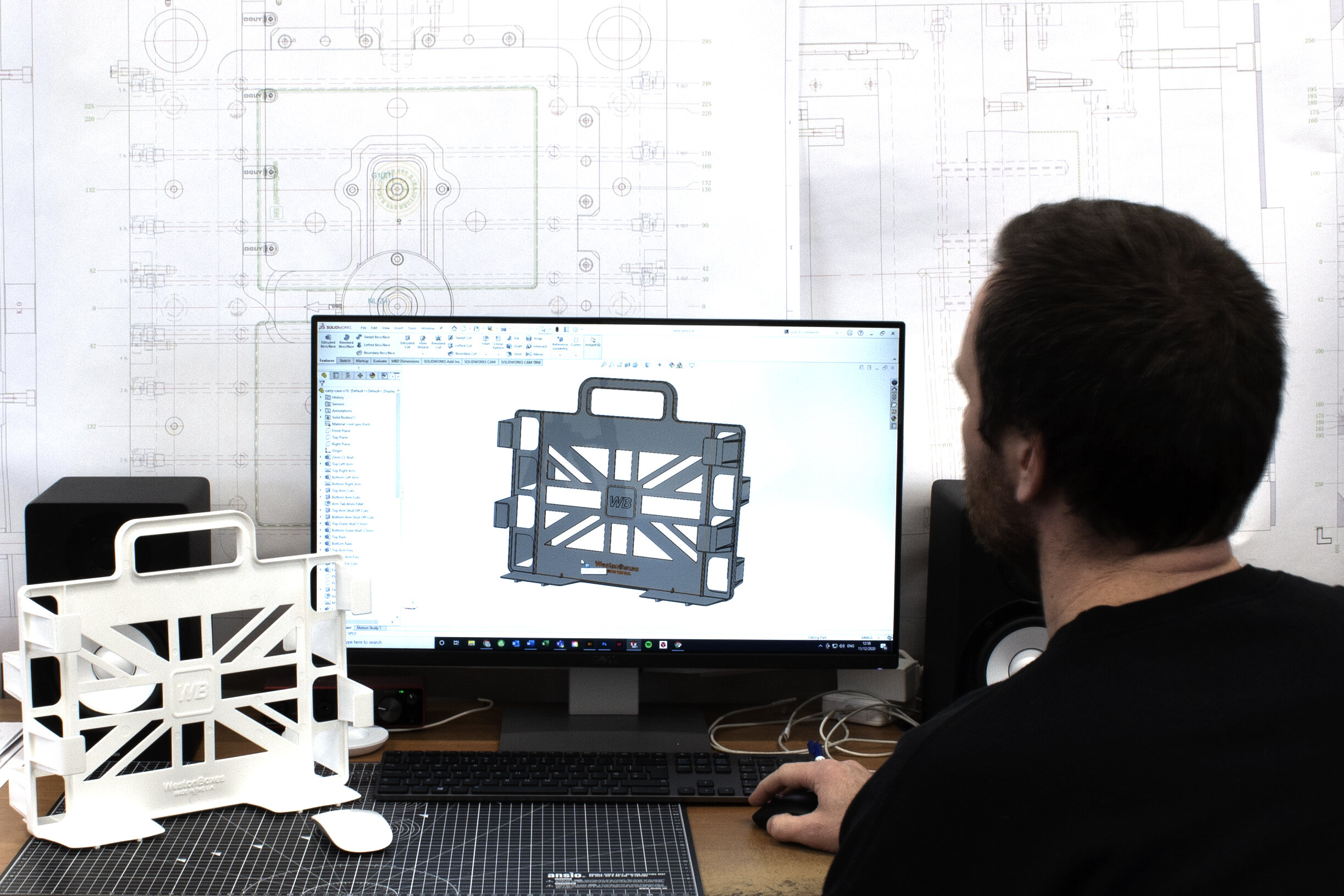

CAD Component Design.

✔ Complimentary DFM (Design for Manufacturability)appraisal,

✔ Material flow analysis ✔ NDA’s provided if required

CAD Drawing Service

We offer a component drawing service producing 3D CAD models from which dimensioned 2D drawings, 3D printed prototypes and eventually, injection mould tooling can be derived. If required we will work with you to develop your part design, applying features to optimise it for the injection moulding process.

Order A 3D CAD Model

Don’t have a 3D CAD model of your part? No problem! Start the process by requesting a free design consultation.

During the consultation our team will gather information from you about your part such as, dimensions, features, interactions, part performance requirements. We’ll take that information and draw up a 3D CAD model to your exact specifications.

If you’ve already created dimensioned drawings or have a prototype model that we can take dimensions from then that will speed up the process but even in the absence of these items we can produce CAD models rapidly.

Contact us below to get started!

Submit A CAD Model

Already have a CAD model of your part? Great! Send us the file and we’ll provide a complimentary DFM (Design for Manufacture) appraisal service.

Our team will review your part and run mouldability checks to reveal any features that might cause problems or add cost to the injection moulding process. We’ll advise on any revisions required to optimize your part for mouldability, confirming these improvements are effective with material flow analysis reports if required.

Once DFM revisions are made to your part, its time to create 3D printed prototypes to confirm your design - read more about our prototyping service here.

Submit your CAD file here to begin the DFM appraisal process.

We’re always happy to provide and sign NDA’s (Non-disclosure agreements) to protect your intellectual property rights.

Component Design for Injection Moulding.

We regularly design components for manufacture by injection moulding using Solidworks CAD software. At all stages in this design process, we draw on our decades of moulding experience and take into consideration key design criteria which are important to ensure final manufactured parts mould successfully. Here’s a look at some of the important points we keep in mind.

1. Material Selection

The choice of plastic material plays a crucial role in the design process. Different plastics have varying properties such as flexibility, strength, thermal resistance, and shrinkage rates. We will select a material that meets the functional requirements of your part while considering its behaviour during the moulding process. Material selection will also influence the cooling time, mould design, and potential for defects like warping or sinking.

2. Wall Thickness

Uniform wall thickness is critical in injection moulding to ensure consistent material flow, cooling, and solidification. Variations in wall thickness can lead to defects such as warping, sink marks, or incomplete fills. We will always aim for a uniform wall thickness throughout the part, typically between 1.5mm and 4mm, depending on the material. If varying thickness is necessary, gradual transitions will be applied to avoid abrupt changes which could cause stress concentrations.

3. Draft Angles

Draft angles are tapered features applied to the vertical walls of the part to facilitate easy removal from the mould. Without sufficient draft, parts may stick to the mould, leading to damage or defects. A typical draft angle ranges from 1° to 2°, but it can be more depending on the depth and texture of the part. Proper draft design ensures smooth ejection, reducing wear and tear on the mould. We will make sure draft angles are applied where required.

4. Ribs and Bosses

Ribs and bosses are structural elements added to reinforce the part without significantly increasing material usage. Ribs will be designed with care to avoid thick sections that could lead to sink marks. Typically, rib thickness will be about 50-60% of the wall thickness. Bosses, often used for mounting or assembly, will be designed with fillets and sufficient draft to ensure smooth material flow and proper filling during the moulding process.

5. Undercuts

Undercuts are features that prevent the part from being ejected from the mould without additional mechanisms like side actions or collapsible cores. While we always try to avoid undercuts because they add complexity and cost to the mould, they may be necessary for certain design features. We will always look to minimize undercuts where possible or use clever design strategies to avoid them, such as incorporating snap-fits or even redesigning a part to split into multiple components.

6. Cooling Considerations

All plastics shrink as they cool and solidify, and different materials have different shrinkage rates. When mould tooling is commissioned for your finalised design we will account for this shrinkage by oversizing dimensions at a specific value appropriate to the material selected. Additionally, we will have already ensured your part suffers minimal warping by applying uniform wall thickness giving balanced material flow paths, and adequate cooling. We confirm these properties with flow analysis software before mould tooling proceeds.

7. Gate Location

The gate is the entry point through which molten plastic flows into the mould cavity. The placement of the gate significantly impacts the flow pattern, filling time, and location of weld lines or voids. We will place the gate in a location that ensures complete and uniform filling, minimizes visible defects, and allows for easy removal of the gate vestige (the small mark left after the gate is cut off). This placement is also confirmed by flow analysis software testing before mould tooling proceeds.

Contact S.B. Weston for CAD drawing services

At S.B.Weston we have extensive experience of injection moulding parts that we have designed in-house, taking into consideration the factors above to create parts and products that are not only functional and aesthetically pleasing but also optimized for efficient and cost-effective manufacturing.

If you need assistance progressing your concept sketches into fully defined 3D CAD models and 2D drawings, ready for prototyping or mold tooling then why not contact us at S.B. Weston to arrange a free, no obligation design consultation. We can look at your project’s exact requirements and advise you how to best proceed. We’re always happy to sign NDA’s to protect your ideas, so why not get in touch, we’d love to help make your project a British manufacturing success!