3D Printing & Rapid Prototypes.

✔ SLA (Stereolithographic)

✔ SLS (Selective Laser Sintering)

✔ FDM (Fused Deposition Modelling)

✔ 3D Print Finishing

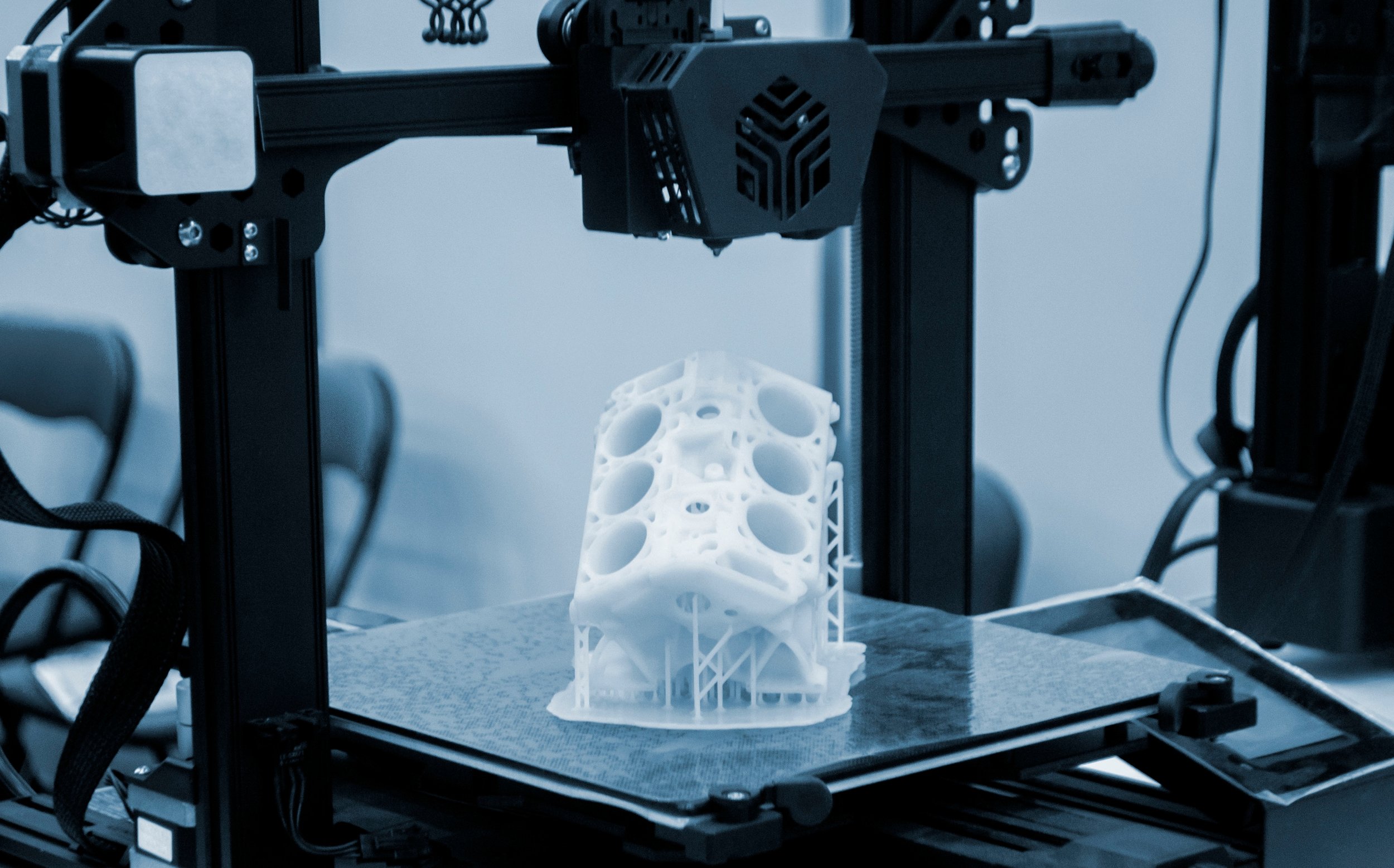

3D Printed Prototypes

Looking for a fast, low cost 3D print service? Simply upload your CAD file below and we’ll return a quote. When developing a part for injection moulding, committing to a mould is the most significant step—both in terms of cost and production. Before making this commitment, we always recommend creating and reviewing a 3D printed prototype. With low costs and fast turnaround times on many types of 3D print and a diverse variety of materials it is a must before proceeding to mould tooling.

Order a 3D CAD Model

To create a 3D print, a 3D CAD model must first be produced. Once you have a 3D CAD model you can create as many 3D prints as required from it. If you need a CAD model of your part we can create one for you. Read more about our CAD drawing service here

Submit A 3D CAD Model

If you already have a CAD model of you rpart then you’re almost ready to go. Send the file across on the button below and we’ll rapidly return a quote for basic 3D prints withour surface finish. In most cases this is all that is required to confirm that the part is designed correctly and functions as it should in real world scenarios.

3D Printed Prototypes: Key Benifits

3D printing, also known as additive manufacturing, is a process that creates three-dimensional objects by layering materials based on digital designs. It starts with a computer model, which is sliced into thin horizontal layers. A 3D printer then builds the object layer by layer, adding material—such as plastic, metal, or resin—according to the design. This technique allows for precise, complex shapes and is used in various fields, from prototyping and manufacturing to medical implants and custom consumer products. Unlike traditional subtractive manufacturing, which cuts away material, 3D printing adds material only where it's needed, reducing waste and enabling intricate designs. During the process of designing and manufacturing an injection moulded part, it has particular advantages and benifits:

1. Cost-Effective Testing

Producing an injection mould tool is expensive, often running into tens of thousands of pounds. By using 3D printing to create a prototype, we can identify design flaws and apply necessary modifications, avoiding costly revisions with the toolmaker later on.

2. Speed and Efficiency

3D printing allows for rapid production of prototypes. In contrast to the weeks or months needed to manufacture and test a traditional mould, a 3D printer can produce a prototype in a matter of hours or days. This acceleration significantly shortens the design iteration cycle.

3. Design Validation and Refinement

A physical prototype helps in assessing the form, fit, and function of the component. We can physically handle the prototype, fit it into assemblies, and perform functional tests that are not possible with CAD models alone. This hands-on review is critical for validating the design before committing to expensive moulds.

4. Material Versatility

3D printing now offers a wide range of materials, from rigid plastics to flexible polymers, which can mimic the properties of your final injection-moulded part. This versatility allows for more comprehensive testing and better prediction of how the final product will behave.

5. Risk Mitigation

By identifying and addressing potential issues early in the design process, 3D printing prototypes reduce the risk of costly delays and product failures, ensuring a smoother transition to mass production.

Examples of 3D Printing Methods

1. Fused Deposition Modeling (FDM)

- FDM is one of the most widely used 3D printing methods. It works by extruding thermoplastic filaments layer by layer to build the prototype. This method is cost-effective and suitable for creating durable and functional parts.

2. Stereolithography (SLA)

- SLA uses a laser to cure liquid resin into hardened plastic in a layer-by-layer process. It produces high-resolution prototypes with excellent surface finishes, making it ideal for detailed and complex designs.

3. Selective Laser Sintering (SLS)

- SLS involves fusing powdered material, typically nylon or other polymers, using a laser. This method is excellent for producing strong, functional prototypes that can withstand rigorous testing.

Contact S.B. Weston for 3D Printed Prototypes

At S.B. Weston we always encourage 3D printed prototypes during the design and development phase before committing to plastic injection mould tooling. Having the physical component to critique provides significant advantages in cost, speed, and risk management. The ability to quickly produce, test, and iterate on physical prototypes ensures that the final design is optimized, functional, and ready for efficient mass production. Embracing various 3D printing methods allows our team to recommend the best approach for your project, ultimately leading to better-designed products.

If you have a component design that you want to discuss or are looking to order a 3D printed prototype but are unsure of the process, then get in touch. Our team are ready to assist!